عشر طرق لتحسين سعة الفصل الجاف

وقت الإصدار: 2025-08-30

جدول المحتويات

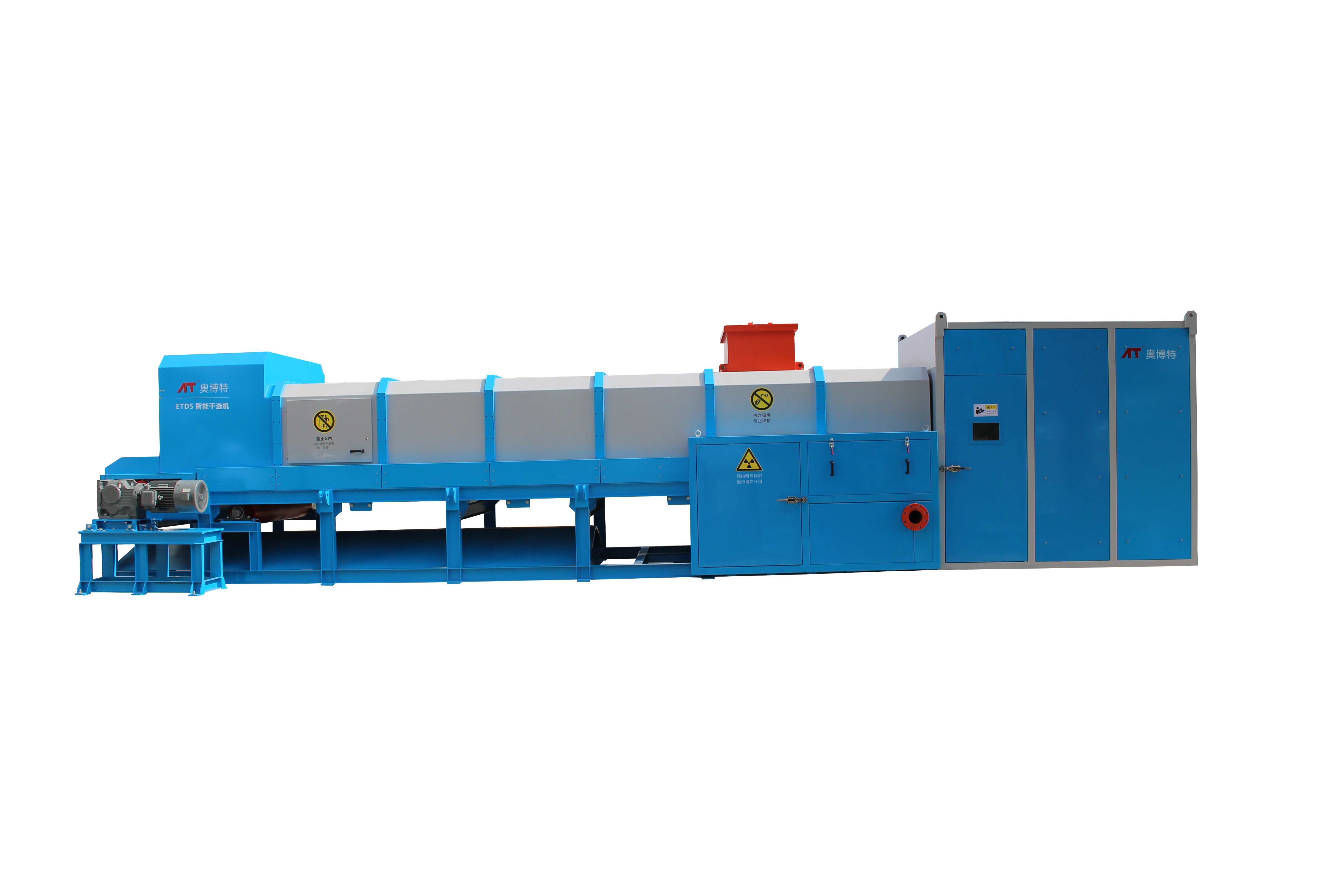

لا يمكن إنكار أهمية الفواصل الجافة في التعدين. معدات فرز عالية الكفاءةتُستخدم هذه الفواصل على نطاق واسع في صناعات مثل تعدين الفحم والمعادن، مما يُحسّن بشكل كبير من استخلاص الخام ودقته. ومع ذلك، مع تزايد ندرة الموارد وتزايد متطلبات العمليات، أصبح تحسين قدرة معالجة الفواصل الجافة قضيةً مُلحة لشركات التعدين. تُقدم هذه المقالة عشر طرق لتحسين قدرة الفواصل الجافة.

تحسين إعدادات معلمات الفصل الجاف

أولاً، يُعدّ ضبط جميع معلمات جهاز الفصل الجاف بشكل صحيح أساسًا لتحسين قدرة المعالجة. فضبط معلمات مثل تدفق الهواء، ومعدل التغذية، وتردد الاهتزاز يضمن تدفق الخام وكفاءة الفرز داخل جهاز الفصل الجاف، مما يُحسّن قدرة المعالجة.

تحسين المعالجة المسبقة للمواد الخام

ترتبط قدرة معالجة جهاز الفصل الجاف ارتباطًا وثيقًا بعوامل مثل حجم جزيئات الخام ونسبة الرطوبة. المعالجة المسبقة المناسبة للمواد الخام، مثل الغربلة والتجفيف، تُحسّن كفاءة جهاز الفصل الجاف بشكل فعال وتُقلل من انسداد المواد داخل الجهاز.

الصيانة والعناية المنتظمة

يضمن الفحص والصيانة الدورية للمعدات التشغيل الفعال طويل الأمد لفاصل التجفيف. تنظيف الغبار من المعدات، وفحص حالة عمل المحرك والمروحة، واستبدال الأجزاء البالية، يُطيل عمر المعدات بشكل ملحوظ ويحافظ على استقرار قدرتها على المعالجة.

ترقية أنظمة التحكم في المعدات

مع تزايد انتشار التكنولوجيا الذكية، ينبغي أيضًا تحديث أنظمة التحكم في أجهزة الفصل الجاف. تتيح أنظمة التحكم PLC الحديثة ومعدات التحكم الآلي التحكم الدقيق والتعديلات الفورية، مما يُحسّن دقة فرز الخام وسرعة المعالجة.

اعتماد تقنيات الفرز المتقدمة

تتطور مبادئ وتقنيات الفرز بالفاصل الجاف باستمرار. على سبيل المثال، يُحسّن استخدام تقنية المجال المغناطيسي القوي وتقنية الفرز بتدفق الهواء دقة فرز الخامات بشكل ملحوظ، خاصةً عند معالجة المواد الدقيقة، مما يزيد من قدرة المعالجة بشكل كبير.

تحسين طرق تغذية المواد

قد تُقلل طرق التغذية غير الصحيحة من قدرة معالجة جهاز الفصل الجاف. من خلال تحسين جهاز التغذية، يُمكن ضمان تشغيله بسلاسة وتجنّب تقلبات قدرة المعالجة الناتجة عن التغذية غير المتساوية.

تقليل استهلاك الطاقة وتحسين كفاءة المعدات

إن تحسين كفاءة الطاقة في جهاز الفصل الجاف لا يُسهم فقط في خفض تكاليف التشغيل، بل يُحسّن أيضًا القدرة الإجمالية للمعالجة. إن اختيار محركات عالية الكفاءة والتحكم الرشيد في استهلاك الطاقة يضمنان القدرة على المعالجة مع تقليل هدر الطاقة.

تحسين مقاومة تآكل المعدات

أجهزة الفرز الجاف معرضة للتآكل أثناء التشغيل لفترات طويلة وبكثافة عالية، وخاصةً في المكونات الرئيسية مثل المصافي والمراوح. لذلك، فإن استخدام مواد أكثر مقاومة للتآكل أو تقوية الأجزاء المعرضة للتلف يمكن أن يقلل من انخفاض قدرة المعالجة الناتجة عن التآكل.

تحسين أتمتة المعدات

عند زيادة سعة المعالجة، يُعدّ تطبيق تقنية الأتمتة أمرًا بالغ الأهمية. تستطيع أجهزة الاستشعار الآلية وأنظمة التنظيف التلقائية مراقبة حالة تشغيل فرزات جافة في الوقت الحقيقي وضبط معلمات المعدات تلقائيًا، مما يحسن بشكل فعال كفاءة فرز الخام وقدرة المعالجة.

تحسين أنظمة مراقبة الجودة

مع تحسين قدرة معالجة آلات الفرز الجاف، يجب على شركات التعدين التركيز أيضًا على جودة المنتج. إن إنشاء نظام شامل لإدارة الجودة وإجراء عمليات تفتيش صارمة للجودة لن يُحسّن كفاءة الإنتاج فحسب، بل سيضمن أيضًا مطابقة جودة المنتج النهائي للمعايير.

خاتمة

إن تحسين قدرة معالجة أجهزة الفرز الجاف لا يساعد شركات التعدين على تحسين كفاءة الإنتاج وخفض التكاليف فحسب، بل يوفر لها أيضًا ميزة تنافسية في سوق شديدة التنافس. فمن خلال الصيانة الفعالة للمعدات، وتحديثات التكنولوجيا، وتحسين أنظمة التحكم، يمكن لشركات التعدين تحسين قدرة معالجة أجهزة الفرز الجاف بشكل كبير وتحقيق نتائج فصل مثالية.

لمزيد من المعلومات حول حلول تقنية الفصل الجاف وتوصيات المعدات، يُرجى التواصل مع فريقنا المتخصص. سيوفر لك Obote حلول الفصل الجاف المخصصة لمساعدة منجمك على تحقيق استخدام أكثر كفاءة للموارد.