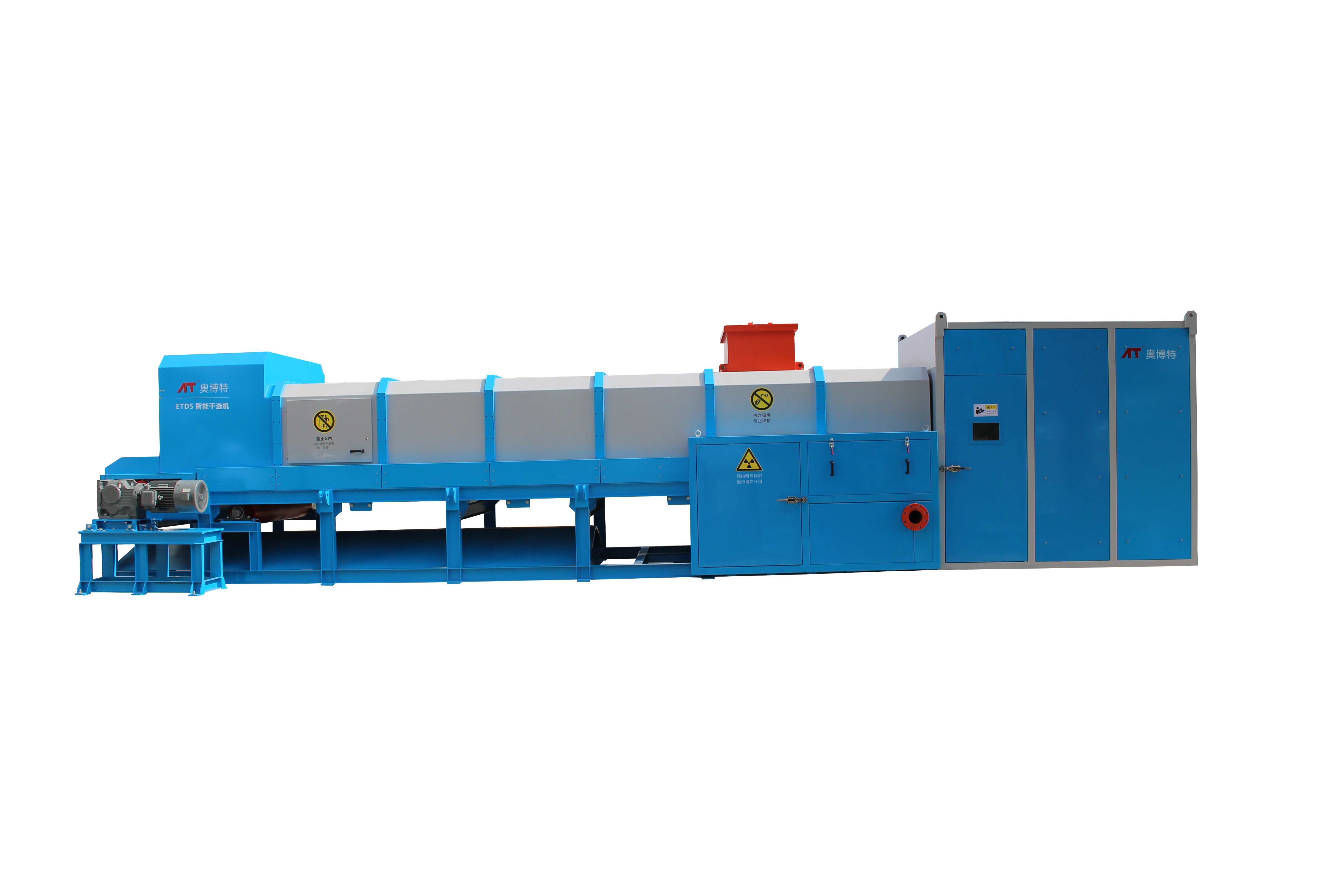

Máquina inteligente de separación de carbón seco Obote: Proceso de separación de carbón

Hora de lanzamiento: 18/06/2025

El Máquina inteligente de separación de carbón seco Obote Utiliza tecnologías y equipos avanzados para separar físicamente el carbón de las impurezas, mejorando así la calidad del carbón y su valor de utilización.

Proceso de separación del carbón:

Preparación de carbón crudo

Tras la extracción del carbón, se transporta mediante equipos de transporte (como una cinta transportadora) hasta el patio de almacenamiento de carbón crudo en la planta de preparación de carbón. Una vez en la planta, el carbón crudo suele someterse a un cribado para su clasificación granulométrica.

Cribado

El cribado es un paso preliminar crítico en el proceso inteligente de separación de carbón seco. El carbón crudo pasa a través de una criba vibratoria, cuyos orificios se ajustan según los requisitos reales, como 50 mm u 80 mm. Tras el cribado, el carbón crudo se clasifica en diferentes tamaños de partícula. Las partículas de mayor tamaño (p. ej., 50-300 mm) se dirigen a... sistema inteligente de separación en seco, mientras que los materiales más pequeños que el tamaño del orificio de la pantalla se tratan como carbón producto o se dirigen a otras etapas de procesamiento.

Separación inteligente

El carbón crudo tamizado entra en el máquina de separación en seco inteligente, con el principio de funcionamiento como sigue:

- Adquisición de información: Mediante fuentes y detectores de rayos X, se recopila información sobre las diferencias elementales del material. Simultáneamente, un conjunto de cámaras de luz visible captura la textura superficial y la reflectividad del material.

- Reconocimiento y Análisis: Se aplican algoritmos de aprendizaje profundo de inteligencia artificial para fusionar y entrenar la información adquirida, identificando carbón y ganga (roca estéril).

- Ejecución de Separación: Con base en los resultados del reconocimiento, se dirige aire a alta presión al material objetivo mediante válvulas electromagnéticas, logrando la separación del carbón y la ganga.

Salida del producto

El carbón y la ganga separados se transportan y almacenan mediante diferentes equipos de transporte:

- Carbón limpio: el carbón limpio clasificado se transporta a través de una cinta transportadora directamente al almacenamiento de carbón limpio, o se puede triturar y mezclar con otros productos de carbón según sea necesario.

- Ganga: La ganga separada se transporta a través de una cinta transportadora al almacén de ganga y finalmente se transporta para su eliminación.

Almacenamiento y transporte de productos

- Almacenamiento de carbón limpio: El carbón limpio generalmente se almacena en contenedores de carbón limpio, con alimentadores en la parte inferior del contenedor para facilitar la carga y el transporte.

- Tratamiento de ganga: La ganga se almacena en el contenedor de ganga y se puede transportar para su eliminación según sea necesario.

Principales ventajas de la separación inteligente de carbón seco de Obote

- Sin agua: resuelve el problema de la separación del carbón en zonas con escasez de agua, evitando la contaminación del agua y el consumo de recursos, sin necesidad de costos de tratamiento de agua de pulpa de carbón ni presiones ambientales.

- Alta precisión de separación: La tecnología de reconocimiento inteligente distingue eficazmente entre carbón y ganga con densidades o características de superficie similares, lo que reduce significativamente el contenido de cenizas del carbón limpio y la tasa de carga de carbón de la ganga.

- Alta automatización: todo el proceso funciona automáticamente, lo que reduce la dependencia del trabajo manual y minimiza los errores operativos.

- Bajo costo operativo: El sistema consume principalmente electricidad y aire comprimido, con un mantenimiento relativamente simple, lo que hace que el costo operativo general sea menor que el de la separación de carbón húmedo.

- Gran adaptabilidad: El proceso es menos sensible a las fluctuaciones en la humedad del carbón crudo en comparación con los métodos húmedos, y el diseño modular del equipo hace que sea fácil de instalar y reubicar.

- Optimización basada en datos: el aprendizaje continuo y la optimización basados en datos mejoran el rendimiento a lo largo del tiempo.