Pertambangan Berkelanjutan 2026: Bagaimana Pemilahan Mineral Non-Logam Kering Merevolusi Kepatuhan ESG

Release time: 2026-02-04

Let’s be real for a second: running a mining operation in 2026 is nothing like it was ten years ago.

If you are managing a site extracting fluorite, quartz, or feldspar, you know the pressure isn’t just coming from the market prices anymore. It’s coming from regulators, local communities, and investors who are obsessed with one acronym: ESG (Environmental, Social, and Governance).

Water permits are getting harder to secure. Tailings dam regulations are becoming a nightmare to navigate. The old way of doing things—”dig, wash, sell”—is quickly becoming a liability.

This is exactly why the industry is witnessing a massive pivot toward non-metallic mineral sorting using dry technology. It’s no longer just a “nice-to-have” upgrade; for many mines in arid regions or strict jurisdictions, it’s becoming the only way to stay in business.

Here is why dry sorting is the unsung hero of the 2026 green mining revolution.

The End of the “Wet Processing” Default

For decades, if you wanted to separate high-grade ore from waste rock, you used water. Lots of it.

Traditional heavy media separation (HMS) or jigging works, but it comes with a heavy price tag. You aren’t just paying for the water; you are paying to treat it, store it, and eventually, clean up the mess it leaves behind in tailings dams.

In the context of modern ESG goals, this is a red flag. Investors are looking at your “water footprint” just as closely as your balance sheet.

This is where advanced non-metallic mineral sorting equipment steps in. By utilizing X-Ray Transmission (XRT) and AI sensors, we can now achieve density-based separation without a single drop of water. We are talking about pre-concentrating ore right at the crushing stage, rejecting waste rock early, and leaving the water out of the equation entirely.

How the Technology Actually Works

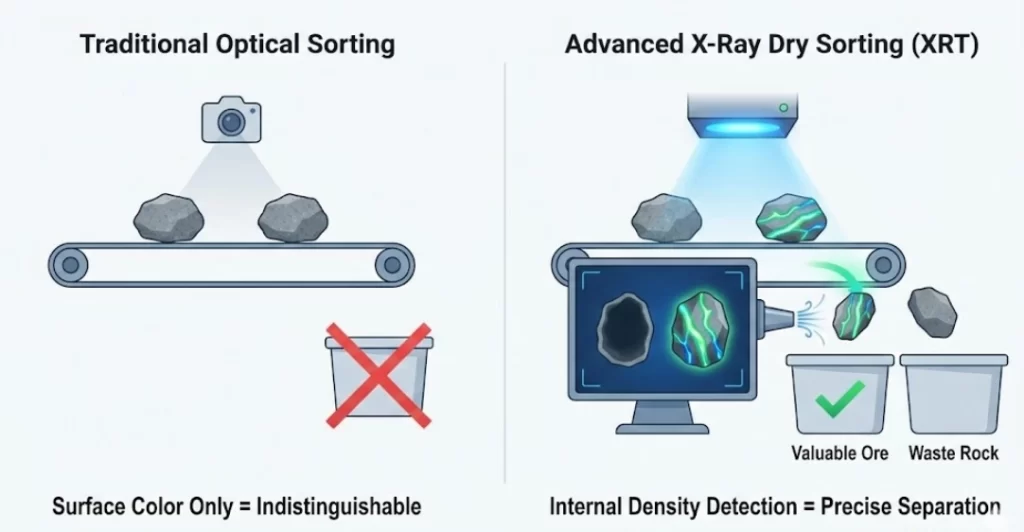

If you are still thinking of “sorting” as those old optical color sorters that only looked at surface color, you need to catch up. The new generation of equipment—like the Huanghe Zhixuan series—goes much deeper.

Modern non-metallic mineral sorting relies on “Dual-Energy X-Ray Transmission.” Think of it like a medical luggage scanner but for rocks. The sensor penetrates the ore, calculating the atomic density of each stone on the belt.

- Color doesn’t matter: a piece of grey waste rock might look identical to grey fluorite on the surface.

- Density is key: the X-ray sees inside. It knows the fluorite is denser.

- The Action: High-speed air jets blow the valuable ore into one bin and let the waste fall into another.

It’s fast, it’s dry, and it’s incredibly precise.

The ESG Scorecard: Why This Tech Wins

Let’s break down how switching to dry non-metallic mineral sorting directly impacts your ESG compliance report.

1. Environmental (The “E”)

This is the big one. By adopting dry sorting, you can reduce your water consumption by up to 90% if you use it for pre-concentration (throwing away waste before it hits the wet mill).

- Less Tailing Waste: Since you are rejecting waste rock dry, you aren’t turning it into wet sludge. Dry tailings are chemically stable, easier to stack, and pose zero risk of a dam failure.

- Lower Energy Bill: You aren’t crushing waste rock. Why spend electricity grinding stone that has no value? By sorting early, you only grind the good stuff.

2. Social (The “S”)

Mines often conflict with local communities over water rights. If your mine is sucking up the local aquifer, the community will push back. By using dry non-metallic mineral sorting equipment, you demonstrate to the local stakeholders that you are a responsible neighbor. You aren’t competing for their water supply. This “Social License to Operate” is invaluable.

3. Governance (The “G”)

Governance is about risk management. Relying on wet processing in a water-scarce area is a massive operational risk. If the water creates a bottleneck, production stops. Dry sorting diversifies your processing line, making your operation resilient against climate risks and regulatory changes.

Real-World Application: Quartz and Fluorite

Let’s look at the numbers. In recent projects involving low-grade fluorite, we’ve seen dry sorting take “waste” dumps (grading around 15-20% CaF₂) and enrich them to over 40-50% pre-concentrate.

Previously, this material was considered trash. Now, it’s feedstock.

For quartz miners, the challenge is often removing heavy impurities like hematite or barite. Non-metallic mineral sorting machines can surgically remove these high-density impurities, protecting the whiteness and purity of the final product without chemical bleaching.

The Bottom Line

We are past the point where environmental compliance was just about ticking boxes. In 2026, efficiency is sustainability.

If you can reduce your operational costs (less water, less energy, less grinding) while simultaneously boosting your environmental rating, it’s a no-brainer.

The shift to dry non-metallic mineral sorting isn’t just about saving the planet—it’s about saving your margin. As we move deeper into this decade, the mines that adapt to dry processing will be the ones that remain profitable and compliant.

Are you ready to see how X-ray dry sorting works for your specific mineral?

[Internal Link: Explore our Huanghe Zhixuan X-Ray Sorting Series here] to see the specs, or contact us to arrange a sample test for your ore.