Maintenance and Operational Management of Non-Metallic Ore Dry Sorting Equipment: Improving Equipment Efficiency and Extending Service Life

Release time: 2025-09-27

Table of Contents

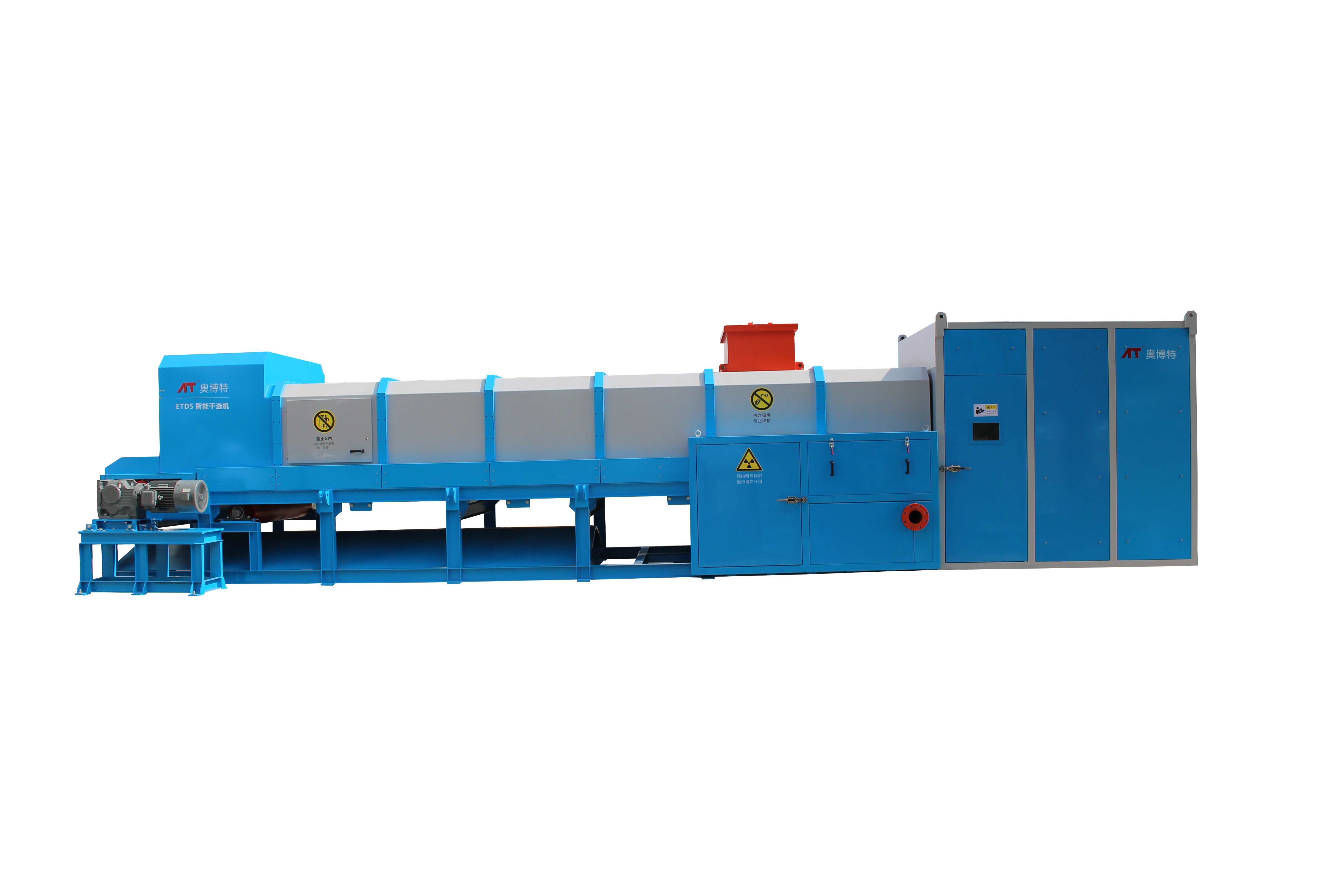

With increasing environmental awareness and demand for resource recovery, non-metallic ore dry sorting equipment is playing an increasingly important role in mineral resource utilization. These equipment not only efficiently separates minerals such as gangue and coal-bearing kaolin, but also effectively reduces environmental pollution during mineral processing. However, to ensure the continued efficient operation of non-metallic ore dry sorting equipment, maintenance and operational management are crucial.

Daily Maintenance: Ensuring Long-Term Stable Operation of Equipment

Daily maintenance and servicing of non-metallic ore dry sorting equipment directly impacts its operating efficiency and service life. First, key components of the equipment, such as the vibrating screen, motor, and airflow system, require regular inspection. Promptly cleaning dust and replacing worn parts can effectively prevent equipment downtime, thereby reducing production costs.

During daily maintenance, the following aspects should be noted:

Cleaning and Lubrication: Regularly clean dust and impurities from the equipment and provide adequate lubrication to key components. Lubricant replacement and inspection are particularly important for equipment operating in high-temperature and high-humidity environments.

Tightening Inspection: During equipment operation, some fasteners may loosen due to vibration or prolonged operation. Therefore, the tightening status of the equipment should be checked regularly to prevent damage caused by loosening.

Filter System Inspection: Dry sorting equipment is typically equipped with a filtration system to prevent impurities from entering the equipment. Regularly inspect and clean the filters to ensure stable operation.

Troubleshooting: Improving Equipment Reliability

Even with good maintenance, equipment can still malfunction after prolonged, high-load operation. Therefore, promptly detecting and troubleshooting faults is another important task to ensure long-term stable operation.

Common faults and their solutions include:

Motor Overload: The motor is the core power source of dry sorting equipment. If an overload occurs, first check whether the motor current is normal and whether the load is excessive. If necessary, adjust the motor speed to prevent damage caused by excessive load.

Uneven Vibration: Uneven vibration of the equipment may be caused by wear on the screen or vibrating components. In this case, the vibrating components should be inspected and any damaged parts replaced promptly.

Material Blockage: Material blockage during dry sorting can affect production efficiency. Therefore, regular inspections of conveyor belts, screens, and airflow systems are essential to ensure they remain unobstructed. Severely blocked areas should be immediately stopped and cleaned to prevent excessive wear and tear.

Intelligent Management: Improving Operational Efficiency

In modern industrial production, intelligent management and automated control have become effective means of improving equipment efficiency and reducing labor costs. The intelligent non-metallic mineral dry sorting equipment not only monitors the equipment’s operating status in real time but also automatically adjusts parameters based on the equipment’s operating conditions to achieve optimal performance.

Advantages of intelligent management systems include:

Real-time Monitoring: Through sensors and monitoring systems, various equipment operating data (such as temperature, current, and vibration) are transmitted to the operating platform in real time, helping operators understand the equipment’s status.

Automatic Alarms: If an equipment anomaly occurs, the intelligent management system automatically issues an alarm, notifying the operator to take appropriate measures, thereby reducing the likelihood of equipment failure.

Data Analysis: The intelligent system uses historical equipment operating data to analyze and predict faults, identifying potential problems in advance and reducing equipment downtime.

Operator Training: Ensuring Efficient Equipment Operation

In addition to routine maintenance and intelligent management, operator training is equally crucial. Only professionally trained operators can ensure efficient and safe equipment operation. Operators should be familiar with the equipment’s operating principles, operating procedures, and troubleshooting methods for common faults. Regular training and technical updates are also crucial to maintaining high operator proficiency.

Conclusion

Maintenance and operational management of X-ray dry sorting equipment for non-metallic mineral are central to ensuring its efficient operation. Regular maintenance, timely troubleshooting, intelligent management, and operator training can effectively improve equipment efficiency, extend its service life, and minimize production downtime. For mining companies, effective equipment management not only reduces operating costs but also increases resource recovery rates and promotes sustainable development.