Obote AI X-Ray Dry Sorting Machine Debuts at IMARC 2025 in Sydney, Leading a Revolution in Mineral Processing Technology

Release time: 2025-11-14

From October 21st to 23rd, 2025, the International Convention Centre Sydney (ICC Sydney) became the focus of the global mining industry. The International Mining and Resources Conference 2025 (Hereinafter referred to as IMARC 2025) was held here, attracting over 11,000 attendees and 550 solution providers from 125 countries. Global mining elites gathered in Sydney, where a revolution in mineral processing / ore sorting technology was quietly unfolding.

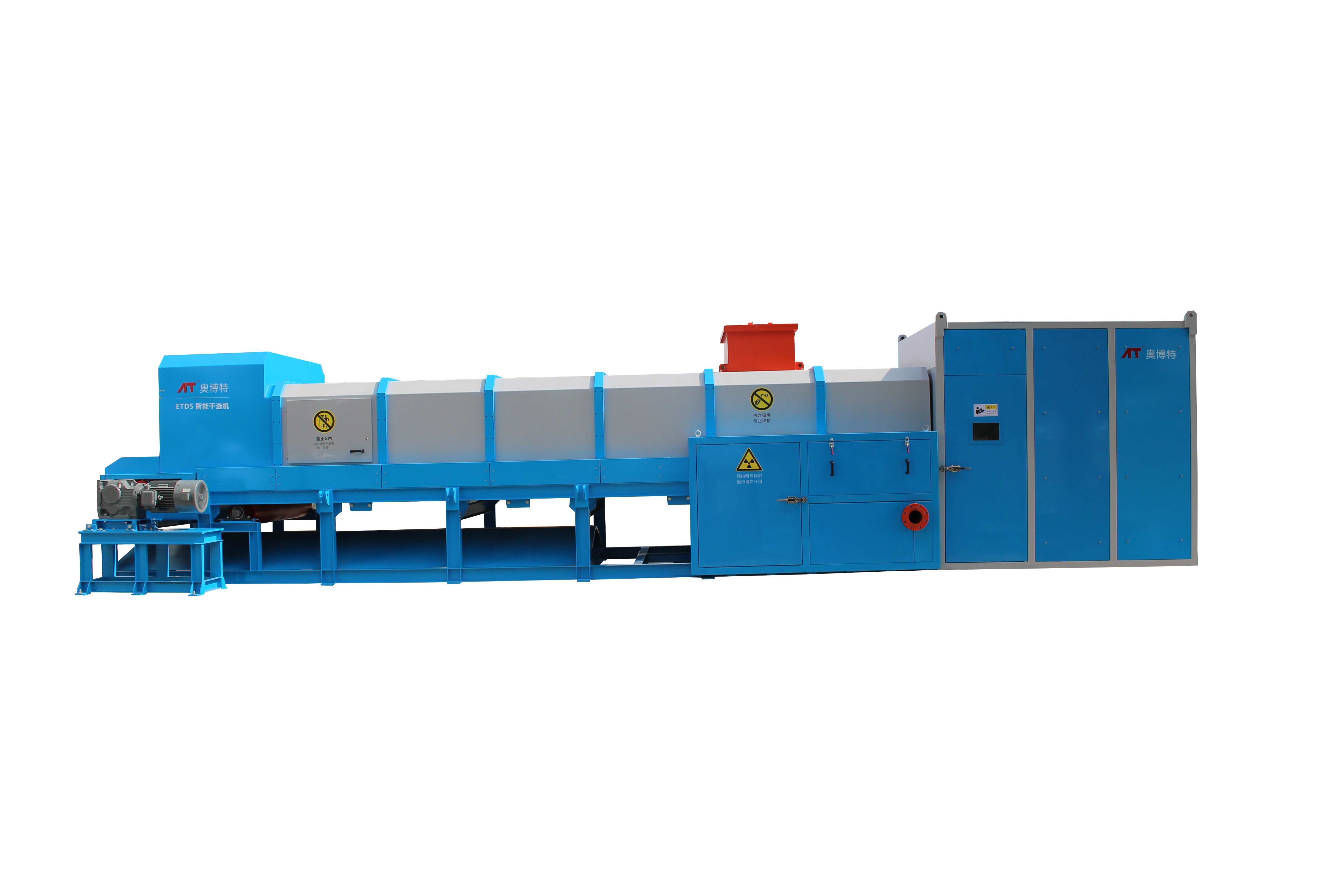

At this largest and most influential mining event in the Asia-Pacific region, Obote AI X-Ray Dry Sorting Machine, as a revolutionary force in mineral processing technology, attracted the attention of numerous mining giants and technical professionals with its unique technological advantages and innovative design.

01 Event Focus: The Global Influence of the Sydney Mining Exhibition

As Australia’s largest and the world’s third-largest mining event, IMARC 2025, with its massive scale and comprehensive exhibits, has become an important platform for technological innovation and business exchange in the global mining industry. The IMARC 2025 exhibition area exceeded 26,000 square meters, with two interconnected exhibition floors, setting a new record for scale. More than 500 mining equipment companies from around the world participated, including international mining giants such as BHP Billiton, Rio Tinto, and Caterpillar. Chinese exhibitors accounted for over 15%, with industry leaders of sorting machinery such as Obote Sorting, XCMG, and Sany Heavy Industry, showcasing their latest technological achievements.

Paul Phelan, IMARC Event Director, stated, “IMARC has become an important platform for the Australian mining and resources industry, to promote technological innovation, facilitate investment, and develop strategic global partnerships.”

02 Technological Innovation: The Core Advantages of Obote AI X-Ray Dry Sorting Machine

In the Smart Mining Zone of IMARC 2025, Obote AI X-Ray Dry Sorting Machine, with its revolutionary technological breakthroughs, became one of the most watched innovative technologies in the mineral processing field.

Compared to traditional mineral processing equipment, Obote AI X-Ray Dry Sorting Machine employs advanced Spectral Analysis and Image Recognition technology, enabling high-precision identification and sorting of ores. This technology, through multi-dimensional scanning of mineral surface composition and internal structure, can complete ore composition analysis and value assessment in a very short time.

Obote AI X-Ray Dry Sorting Machine’s data processing system, equipped with deep learning algorithms, continuously optimizes sorting accuracy, with its recognition accuracy improving over time.

Obote AI X-Ray Dry Sorting Machine’s dry sorting process eliminates the need for water, completely changing the traditional mineral processing model that relies on large amounts of water, providing a viable solution for arid mining areas and regions with scarce water resources, especially suitable for Coal Mine Dry Sorting.

Furthermore, Obote AI X-Ray Dry Sorting Machine, features a modular design, facilitating transportation, installation, and maintenance, significantly reducing operating costs.

03 Market Driver: The Urgent Need for Intelligent Dry Sorting Technology

The demand for intelligent mineral processing technology in the Australian mining market is growing rapidly. According to exhibition data, Australia’s annual growth rate of demand for X-Ray Sorting Machine imports reached 12%, indicating a huge market potential for intelligent Mining Dry Sorting Machine.

Australia possesses abundant mineral resources, ranking first in the world in reserves of lead-zinc(Lead-Zinc Ore AI X-Ray Mining Dry Sorting Machine), nickel(Nickel Ore AI X-Ray Mining Dry Sorting Machine), and uranium(Uraninite Uranium Ore AI X-Ray Mining Dry Sorting Machine), and among the top producers of lithium(Lithium Ore AI X-Ray Mining Dry Sorting Machine), gold(Gold Ore AI X-Ray Mining Dry Sorting Machine), bauxite(Bauxite AI X-Ray Mining Dry Sorting Machine), copper(Copper Ore AI X-Ray Mining Dry Sorting Machine) and iron(Iron Ore AI X-Ray Mining Dry Sorting Machine) ore globally. The efficient development of these resources urgently requires the support of innovative technologies.

At the IMARC 2025 forum, several experts pointed out that traditional mineral processing methods are no longer sufficient to meet the current needs of mining development, especially in a country like Australia facing water scarcity and increasingly stringent environmental requirements.

The Australian government’s “Critical Minerals Strategy” provides strong policy support for innovative technologies, including a 10% tax credit (2028-2040) and government subsidies for critical mineral development. These policies create favorable conditions for the promotion and application of the Obote AI X-Ray Dry Sorting Machine.

04 Practical Value: Efficiency Transformation in Mining Operations

Obote AI X-Ray Dry Sorting Machine demonstrates multiple competitive advantages in actual operation.

(1) It significantly reduces mineral processing costs. Traditional wet separation methods require significant water resources and tailings treatment facilities, while dry separation machines require almost no water, reducing the tailings treatment process.

(2) Its small footprint makes it easy to install and use in space-constrained mining areas. Its modular design allows for rapid deployment and quick operation.

(3) Its separation efficiency is another significant advantage. Its energy consumption per unit of ore processed is more than 30% lower than traditional methods, while simultaneously increasing the recovery rate of useful minerals.

(4) In terms of environmental performance, its dry separation technology completely eliminates the risk of tailings dam failure and the possibility of groundwater pollution from mineral processing wastewater, making mining development more environmentally friendly and safer.

(5) Equipped with an intelligent system, it can collect and analyze production data in real time, providing decision support for mine management and helping mining enterprises achieve digital transformation.

05 Application Prospects: A Vast Market Awaits Development

The technical characteristics of Obote AI X-Ray Dry Sorting Machine, give it broad application potential in multiple mining sectors.

(1) In the beneficiation of strategic mineral resources such as lithium(Lithium Ore AI X-Ray Mining Dry Sorting Machine) and rare earth(Bastnaesite Rare Earth AI X-Ray Mining Dry Sorting Machine, Monazite Rare Earth AI X-Ray Mining Dry Sorting Machine, Xenotime Rare Earth AI X-Ray Mining Dry Sorting Machine), high-precision separation capabilities of Obote AI X-Ray Dry Sorting Machine, can significantly improve resource utilization.

(2) For low-grade minerals, traditional methods are often uneconomical, while Obote AI X-Ray Dry Sorting Machine makes the development of these resources feasible, by effectively separating valuable minerals from gangue.

(3) In the coal(Coal Mine AI X-Ray Mining Dry Sorting Machine) industry, Obote AI X-Ray Dry Sorting Machine, can effectively remove coal gangue(Coal Gangue AI X-Ray Mining Dry Sorting Machine) and impurities from ore with coal mine dry sorting technology, improving coal quality while reducing transportation costs.

(4) Small mines and mines in remote areas often cannot afford the high investment costs of traditional beneficiation facilities, while the modular and mobile solutions of Obote AI X-Ray Dry Sorting Machine, perfectly meet these needs.

- With the advancement of sustainable development in the mining industry, Obote AI X-Ray Dry Sorting Machine, is also expected to play an important role in areas such as construction waste recycling(Construction Waste Recycling Asphalt Brick Concrete, AI X-Ray Mining Sorting Machine) and electronic / metal waste sorting(Construction Waste Recycling Aluminum Copper, AI X-Ray Mining Sorting Machine).

At IMARC 2025, several mining giants expressed strong interest in Obote AI X-Ray Dry Sorting Machine, with technical experts from companies including Rio Tinto, BHP Billiton, and Caterpillar visiting the booth to experience this innovative technology firsthand.

As the global mining industry accelerates its transformation towards smart and green technologies, Obote AI X-Ray Dry Sorting Machine is poised to play a significant role in Australia’s $50 billion mining infrastructure investment market.

As IMARC Director Paul Phelan stated, “IMARC is a bridge connecting Australian mining innovation with the world.” Obote AI X-Ray Dry Sorting Machine is a rising star on this bridge.