Интеллектуальная технология сухой сортировки повышает эффективность сортировки руды

Время выпуска: 21 июля 2025 г.

В горнодобывающей промышленности сортировка руды, также известная как обогащение, переработка руды или обогащение минералов, является важнейшим технологическим процессом. Основная цель — переработать добытую руду в концентрат с более высокой экономической ценностью, одновременно отделив и удалив бесполезные пустые породы.

Основными задачами сортировки руд являются:

Улучшение качества руды

Как правило, сырая руда содержит большое количество ненужных камней, почвы и других малоценных или бесполезных минералов. оборудование для сортировки рудыФизическими, химическими или физико-химическими методами полезные минералы могут быть сконцентрированы в процессе сортировки. Это значительно повышает содержание или качество ценных элементов или полезных ископаемых (например, угля или промышленных минералов) в концентрате. Поскольку концентрат значительно ценнее рудного сырья, он соответствует требованиям к качеству для последующей плавки или непосредственного использования.

Сокращение затрат на транспортировку и переработку

- Объёмы сырой руды огромны и содержат большое количество пустой породы. Удаление пустой породы на руднике или близлежащем сортировочном заводе значительно сокращает объём материала, требующего перевозки на большие расстояния, что существенно экономит транспортные расходы.

- Последующие процессы, такие как плавка и химическая обработка, часто требуют значительных затрат по тоннажу или являются энергоёмкими. Уменьшение общего объёма перерабатываемого материала может значительно снизить затраты и энергопотребление на этих последующих операциях.

Повышение эффективности и экономичности последующей плавки/обработки

- Высокосортные концентраты полнее и быстрее реагируют в плавильной печи, что повышает показатели извлечения металла.

- Сокращение количества бесполезной пустой породы во время плавки снижает расход топлива, расход флюса и образование шлака.

- Некоторые вредные примеси (такие как сера, мышьяк, фосфор и т. д.) частично удаляются в процессе сортировки, что снижает нагрузку на окружающую среду и сокращает затраты на переработку и очистку.

Комплексное извлечение полезных ископаемых

Многие рудные тела содержат несколько ценных минералов. Благодаря различным процессам сортировки, сопутствующие ценные минералы могут быть разделены на концентрацию и извлечение (например, извлечение молибдена, золота и серебра из медной руды; извлечение свинцового и цинкового концентратов из свинцово-цинковой руды). Это позволяет максимально эффективно использовать ресурсы и повысить общую экономическую эффективность рудника.

Снижение воздействия на окружающую среду

- Сокращение количества хвостов: путем эффективной сортировки и удаления больших объемов пустой породы с использованием интеллектуальный сухой сепараторОбъём образующихся хвостов, требующих хранения, значительно сокращается. Это снижает нагрузку на землепользование, строительство и обслуживание хвостохранилищ, а также риск их прорыва.

- Сокращение вредных выбросов: интеллектуальная сортировка позволяет удалять некоторые кислые минералы или другие вредные элементы, снижая риск попадания этих веществ в хвостохранилища или последующие процессы плавки, тем самым снижая риск дренажа кислых шахтных вод и выбросов токсичных газов/пыли.

- Снижение общего потребления энергии и выбросов углерода. Как упоминалось ранее, сокращение объемов транспортировки и переработки приводит к снижению потребления энергии и выбросов углерода.

Повышение ценности бедных рудных тел

Некоторые рудные тела содержат низкое количество руды, из-за чего прямая добыча, транспортировка и плавка обходятся слишком дорого, чтобы быть рентабельной. Эффективная технология сортировки позволяет концентрировать эти низкосортные руды в высококачественные концентраты, превращая ресурсы, добыча которых в противном случае была бы экономически невыгодной, в извлекаемые, тем самым продлевая срок службы рудника.

Предварительная сортировка руды

Процесс сортировки обычно включает такие этапы, как дробление и просеивание, где руда классифицируется по размеру частиц. Для руд с разным размером частиц или минеральным составом могут потребоваться разные методы сортировки (например, для крупных частиц может использоваться гравитационное разделение, а для мелких — флотация). Предварительная сортировка помогает оптимизировать эффективность последующих процессов сортировки.

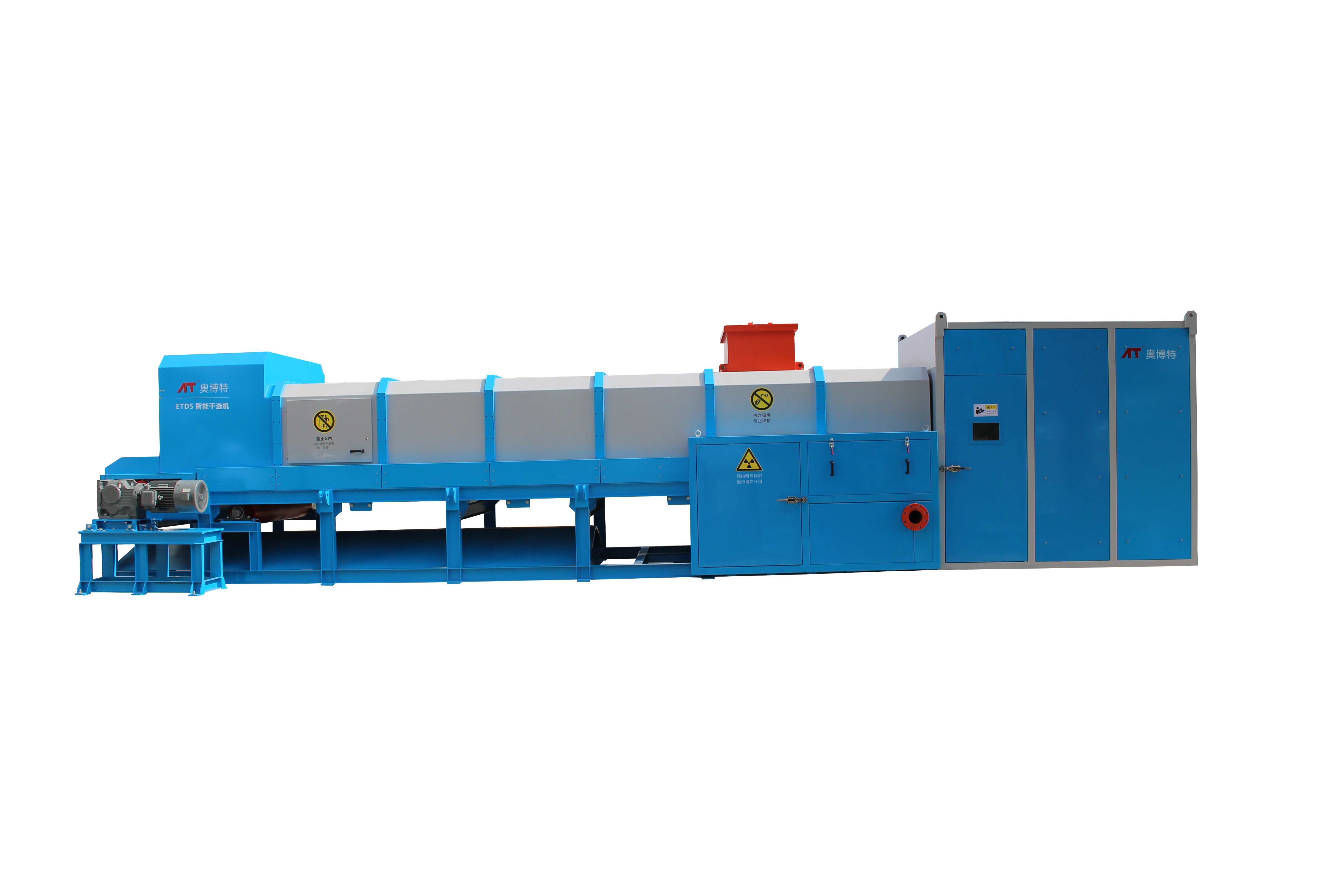

Сортировка руды – это битва за «извлечение золота из пустой породы». Речь идёт не только о разделении; это знаменует собой радикальный переход горнодобывающей промышленности от ресурсоёмких к технологичным операциям. Новое поколение отечественного технологического оборудования, представленное Интеллектуальный сухой сепаратор Oboteоткрывает двери к «эффективности на основе источников и экологически чистому производству» для горнодобывающих компаний посредством совместных инноваций пяти основных систем: подача, идентификация, исполнение, контроль и защита окружающей среды.