От традиционной мокрой обработки к интеллектуальной сухой сортировке: как шахты сокращают затраты за счет «предварительной концентрации»

Release time: 2025-12-09

Оглавление

In 2026, as the global mining industry pivots toward green mining and digital transformation, managing low-grade ores while reducing Operating Expenses (OPEX) has become a matter of survival. Traditional mineral processing often relies on water-intensive methods and high-energy grinding. However, in an era of declining ore grades, интеллектуальное оборудование для сухой сортировки is redefining the industry’s Return on Investment (ROI) through the power of pre-concentration.

What is Pre-concentration? The Key to “Unloading” Your Process

Pre-concentration, also known as “Pre-sorting,” refers to the process of identifying and removing waste rock using intelligent dry sorters before the ore enters the energy-intensive Ball Mill stage.

While traditional logic dictates “grind everything and then float,” Obote Sorting’s intelligent solutions advocate for “sorting before grinding.” Utilizing high-precision X-ray transmission (XRT) technology, the system detects density variations within the ore in milliseconds. High-pressure air nozzles then precisely eject waste rock from the Run-of-Mine (ROM) feed.

Core Value: How Intelligent Dry Sorters Slash Mining Costs

For B2B mining clients, implementing an automatic ore sorting system is not just a technical upgrade; it is a direct driver of profit growth:

Reduction in Energy and Grinding Media Consumption: Grinding typically accounts for over 60% of total mineral processing costs. By rejecting 30%–50% of waste rock early, the feed grade is significantly improved. This means power consumption and steel ball wear in the ball mill drop drastically for the same final output.

Achieving “Zero Water Consumption” Operations: In arid or high-altitude regions, the cost of water acquisition is prohibitive. Intelligent dry sorting technology requires no media and no water, solving the pressures of water scarcity and tailings dam management at the source.

Increased Plant Capacity: By removing barren waste before it hits the mill, you effectively increase the annual throughput of your existing facility without investing in expensive mill expansions.

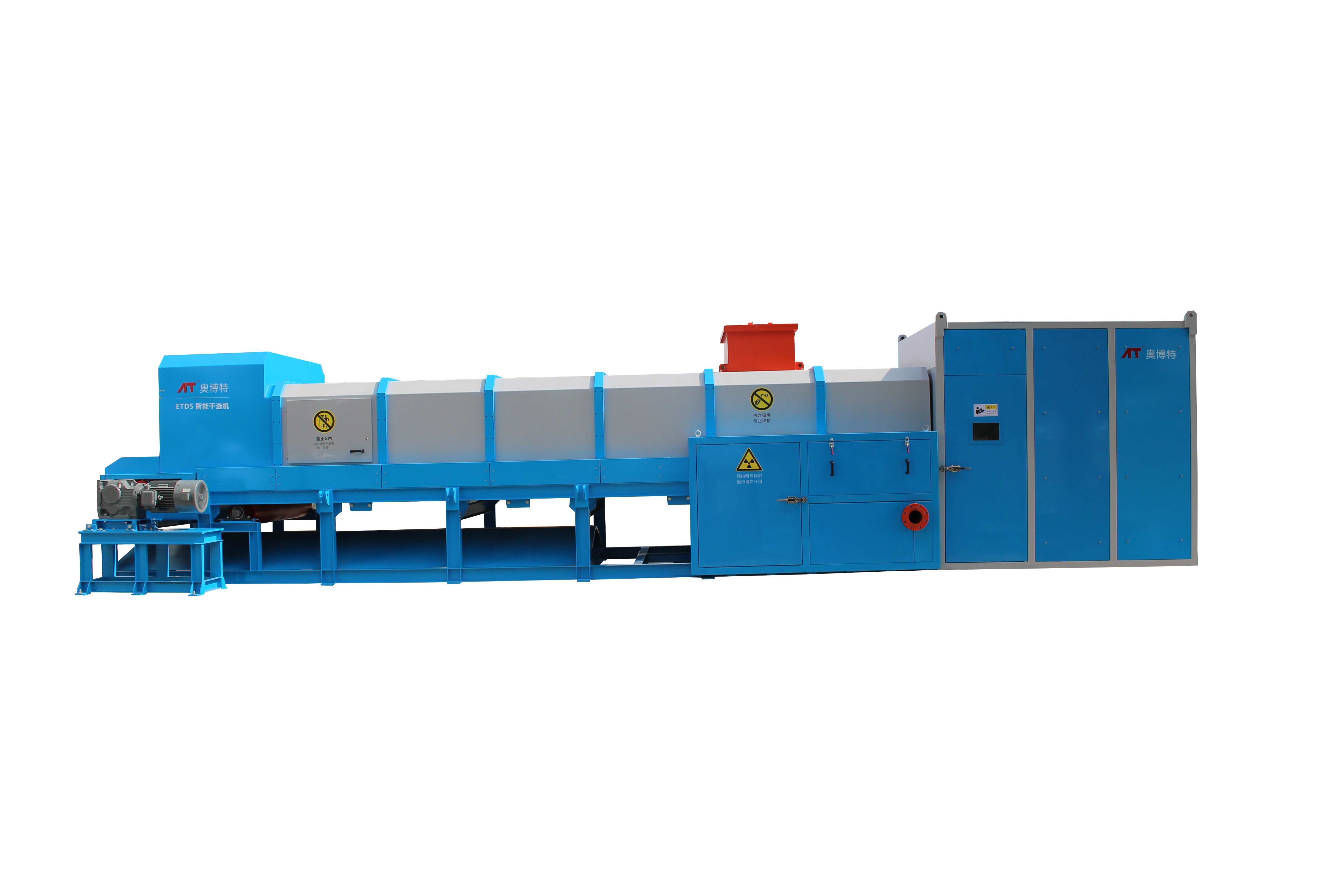

Technical Attributes of Obote Intelligent Dry Sorting Equipment

As a professional mining sorting equipment supplier, Obote focuses on providing stable, high-performance solutions with industry-leading algorithms:

High-Precision Sensor Arrays: Integrated with AI deep learning, our systems handle a wide range of particle sizes and complex mineral compositions, ensuring extremely low recovery loss.

Digital Management Platform: Our equipment features remote monitoring, providing real-time data on rejection rates and feed grades to support smart mine initiatives.

Cost-Effective Maintenance: The modular design allows for quick replacement of consumables, significantly reducing scheduled downtime and maintenance costs.

Conclusion: Investing in Dry Sorting is a Long-term Strategic Move

Under the push of global Carbon Neutrality policies, mining companies face rigorous environmental audits. Choosing an efficient intelligent ore sorting system is not only a response to immediate cost pressures but also an alignment with future “Green, Energy-saving, and Efficient” industry standards.

If you are seeking to improve your mineral processing ROI or need a customized sorting solution for specific minerals (such as coal, non-ferrous metals, or industrial minerals), Obote Sorting provides the technical expertise to optimize your flow sheet.