What are the Advantages of Intelligent Dry Coal Separation Machine?

Release time: 2025-05-07

The intelligent dry coal sorting machine has significant advantages in the coal mining sorting field, especially in improving coal resource recovery efficiency, reducing costs, and environmental protection.

Key Advantages:

High-Precision Sorting

Precise Coal Quality Identification: The intelligent dry coal sorting machine uses advanced sensors and image recognition technologies to accurately differentiate between different coal qualities, achieving efficient and precise sorting. This maximizes the coal mine’s resource recovery rate and minimizes waste.

Fine Particle Sorting: Compared to traditional sorting methods, the intelligent dry coal sorting machine can handle smaller coal particles, even sorting out fine coal powder and impurities, improving the recovery rate of fine-grade coal.

High Automation

No Manual Intervention Required: The intelligent dry coal sorting machine operates fully automatically through AI algorithms and an automated control system. It adjusts work parameters based on real-time data, reducing manual intervention and improving operational efficiency.

Real-Time Monitoring and Adjustment: The system can continuously monitor the properties of the coal and automatically adjust the sorting strategy, ensuring that the sorting effect remains at optimal levels and eliminating sorting errors caused by human factors.

Environmental Protection and Energy Efficiency

Water-Free Sorting: Unlike traditional wet sorting, the intelligent dry coal sorting machine employs dry sorting technology, eliminating the need for water, thus avoiding water resource wastage and pollution issues.

Reduced Waste: The intelligent dry coal sorting machine effectively removes impurities from the coal, reducing the generation of waste coal slurry and environmental pollution, in compliance with environmental regulations.

Increased Coal Recovery Rate

High Recovery Rate: The intelligent dry coal sorting machine performs fine sorting of coal, improving the recovery rate of low-grade coal. It efficiently separates valuable coal from impurities, enhancing overall resource utilization in the coal mine.

Reduced Unqualified Coal: Through intelligent sorting, the proportion of unqualified coal in the coal mine is reduced, improving the overall quality of coal and ensuring the competitiveness of coal products in the market.

Intelligent Learning and Optimization

Machine Learning and Data Analysis: The intelligent coal sorting machine continuously learns from different coal samples and optimizes sorting algorithms through big data and machine learning technologies, further improving sorting precision.

Strong Adaptability

Adaptable to Various Coal Types: The intelligent dry coal sorting machine can meet the sorting needs of various coal types, including different particle sizes, grades, and impurities.

Adaptability to Complex Environments: With advanced sensors and algorithms, the intelligent dry coal sorting machine can operate stably in complex environments, such as high humidity and large temperature fluctuations, maintaining a consistent sorting effect.

Enhanced Safety

Reduced Human Contact: The intelligent dry coal separation equipment reduces the need for manual operation, minimizing the time personnel spend in the coal mine, thus reducing safety risks associated with coal dust and hazardous environments.

Automated Control System: The automated control system monitors the equipment in real-time, and in case of anomalies, the system can automatically alert or shut down to ensure the safe operation of the equipment.

Cost Effectiveness

Reduced Long-Term Operating Costs: Although the initial investment in the intelligent dry coal sorting machine is higher, its high sorting efficiency, reduced labor costs, and improved coal recovery rates significantly lower operating costs over time, yielding higher economic benefits.

Improved Coal Mine Profitability: By improving coal quality and recovery rates through intelligent sorting, the overall value and market competitiveness of the coal mine are enhanced, thus boosting the profitability of the enterprise.

Remote Monitoring and Maintenance

Remote Monitoring System: Many intelligent dry coal sorting machines are equipped with remote monitoring features, allowing real-time viewing of equipment status, production data, and fault alerts. This facilitates equipment maintenance and management, and helps identify potential problems to prevent faults.

Predictive Maintenance: By analyzing real-time data and using machine learning, the equipment can provide early warnings of potential faults, enabling preventive maintenance, reducing downtime and repair costs.

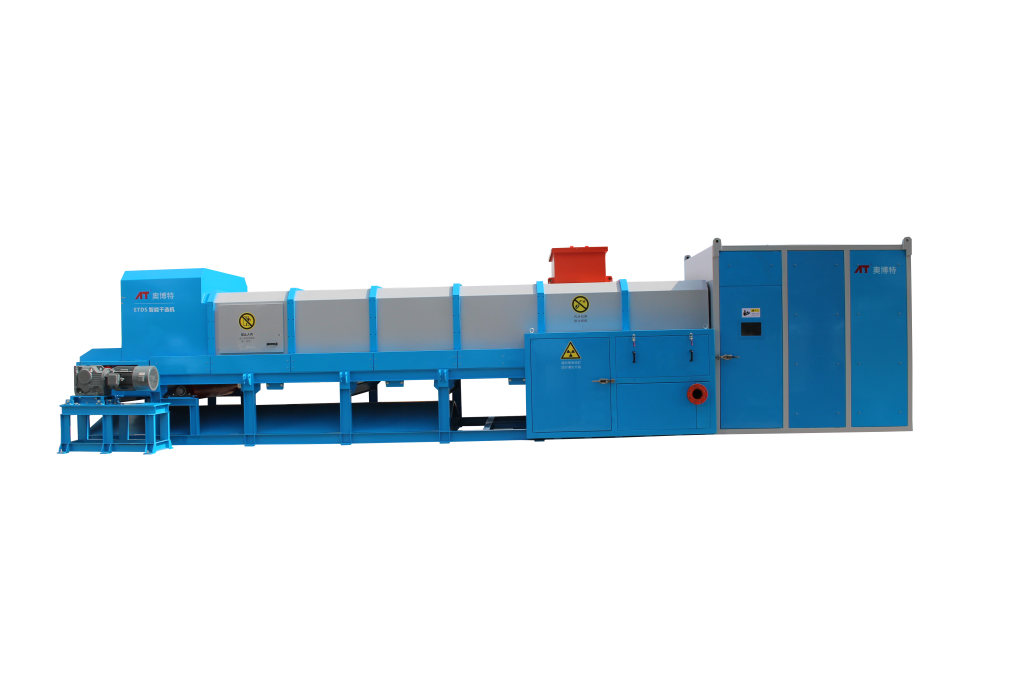

The Obote Intelligent Dry Coal Sorting Machine, with its high-precision sorting, automation, environmental friendliness, energy efficiency, and reduced labor costs, has become an indispensable piece of equipment in the coal mining industry. We look forward to your choice.