What are the core technologies of intelligent dry coal preparation?

Release time: 2025-04-18

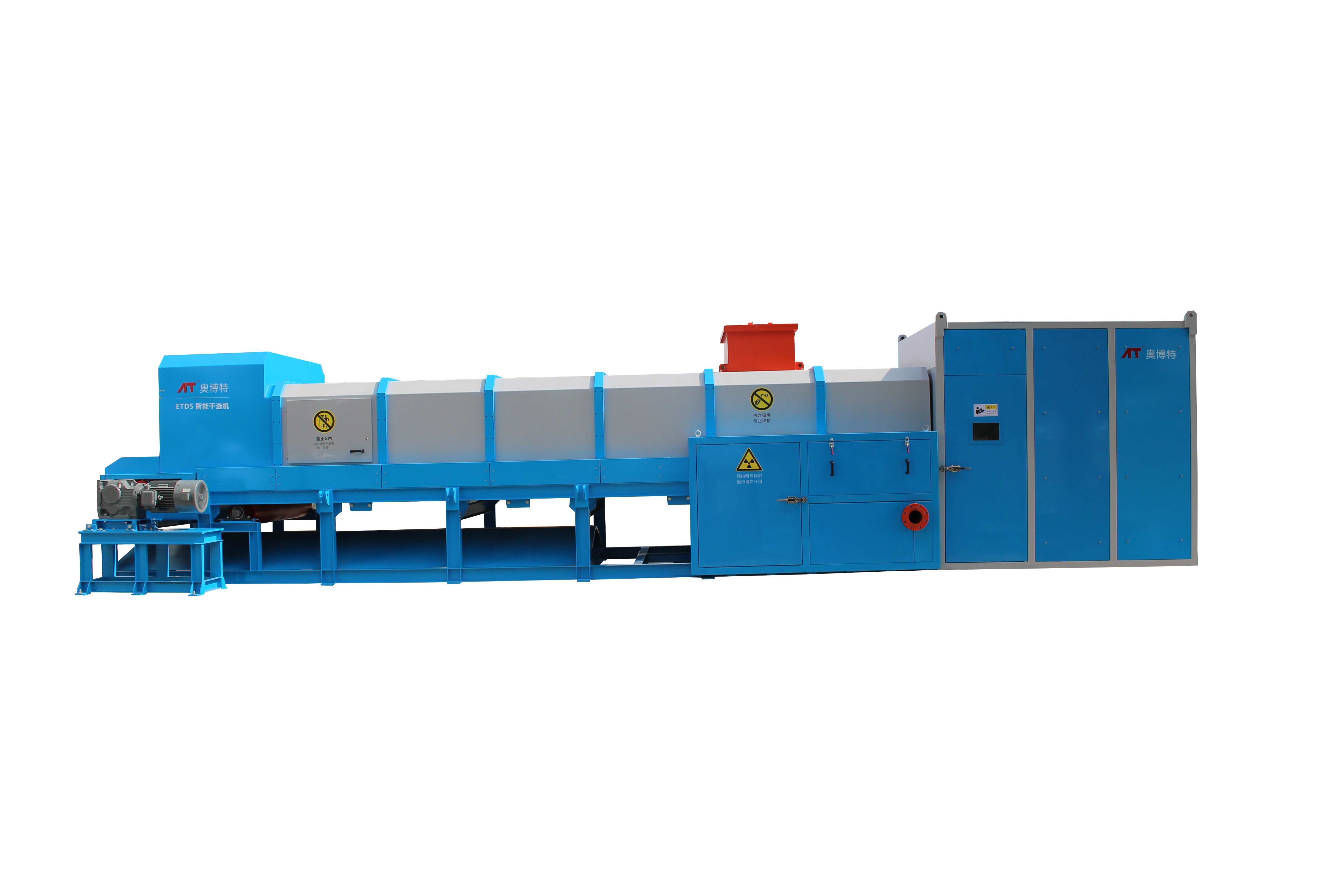

The core technology of intelligent dry coal separation mainly relies on intelligent equipment, sensor technology, data analysis and control system. By integrating advanced technology and equipment, intelligent dry separation equipment can efficiently separate minerals of different particle sizes and qualities in coal, and achieve efficient and low-energy coal separation.

Intelligent control technology

Intelligent dry coal preparation equipment is equipped with an automated control system that can automatically adjust operating parameters and optimize the coal preparation process according to the characteristics of coal and changes in the production environment.

Sensor technology

Sensors are the core components of intelligent dry coal preparation equipment and can monitor the physical and chemical properties of coal in real time. Common sensors include:

X-ray perspective sensors: used to distinguish useful substances from waste in coal, and achieve efficient identification based on the difference in the absorption of X-rays by different components.

Laser particle size sensor: real-time measurement of coal particle size distribution, automatic adjustment of the coal preparation process.

Density sensor: by detecting the density of coal particles, more accurate material sorting can be achieved.

Image processing and machine vision technology

The machine vision system uses high-resolution cameras and image processing algorithms to accurately identify coal surface features, such as shape, color, and particle differences, to improve sorting efficiency. Combined with AI algorithms, it further improves sorting accuracy and automation.

Physical sorting technology

Intelligent dry sorting equipment uses air flotation, vibration screening, airflow sorting and other technologies to separate coal and waste through physical differences (such as density, shape, and particle size). The main technologies include:

Airflow sorting: using airflow differences to separate light and heavy materials.

Bubble sorting: separating minerals of different densities through bubble flotation.

Cyclone sorting: using density differences to separate coal and gangue.

Artificial Intelligence and Big Data Analysis

Intelligent dry sorting equipment integrates AI technology to analyze and optimize the coal sorting process through machine learning and deep learning algorithms. AI can predict changes in coal properties, automatically adjust equipment status, achieve fault warning and self-repair, and continuously optimize sorting accuracy and efficiency.

Energy-saving and emission-reduction technology

Intelligent dry sorting equipment optimizes energy efficiency and reduces energy waste through low-energy sorting methods, intelligent control systems and efficient transmission devices, and adopts advanced vibration screening and airflow sorting methods to reduce water resource use and achieve energy-saving and environmental protection goals.

Automation and remote monitoring technology

Modern intelligent dry sorting equipment has fully automated operation and remote monitoring functions, and operators can monitor, collect data and control equipment in real time. The remote diagnosis system can report faults in a timely manner, reduce downtime and improve production efficiency.

Intelligent dry coal preparation equipment combines intelligent control, precise sensing, physical sorting, AI and big data analysis to achieve efficient and accurate coal preparation, improve recovery rate and efficiency, reduce energy consumption and cost, and promote the intelligent upgrading of the coal industry.